SiOC-Coal Composites

Our SiOC Coal Composite Anodes are Coal Reimagined

The Coal Composite Anode research was initially funded by the Department of Energy’s National Energy Technology Laboratory.

Award Number: DE-FE0031879

3-Year $1 Million, Research Contract

Scaled the technology in 18650 cells

Performance Data

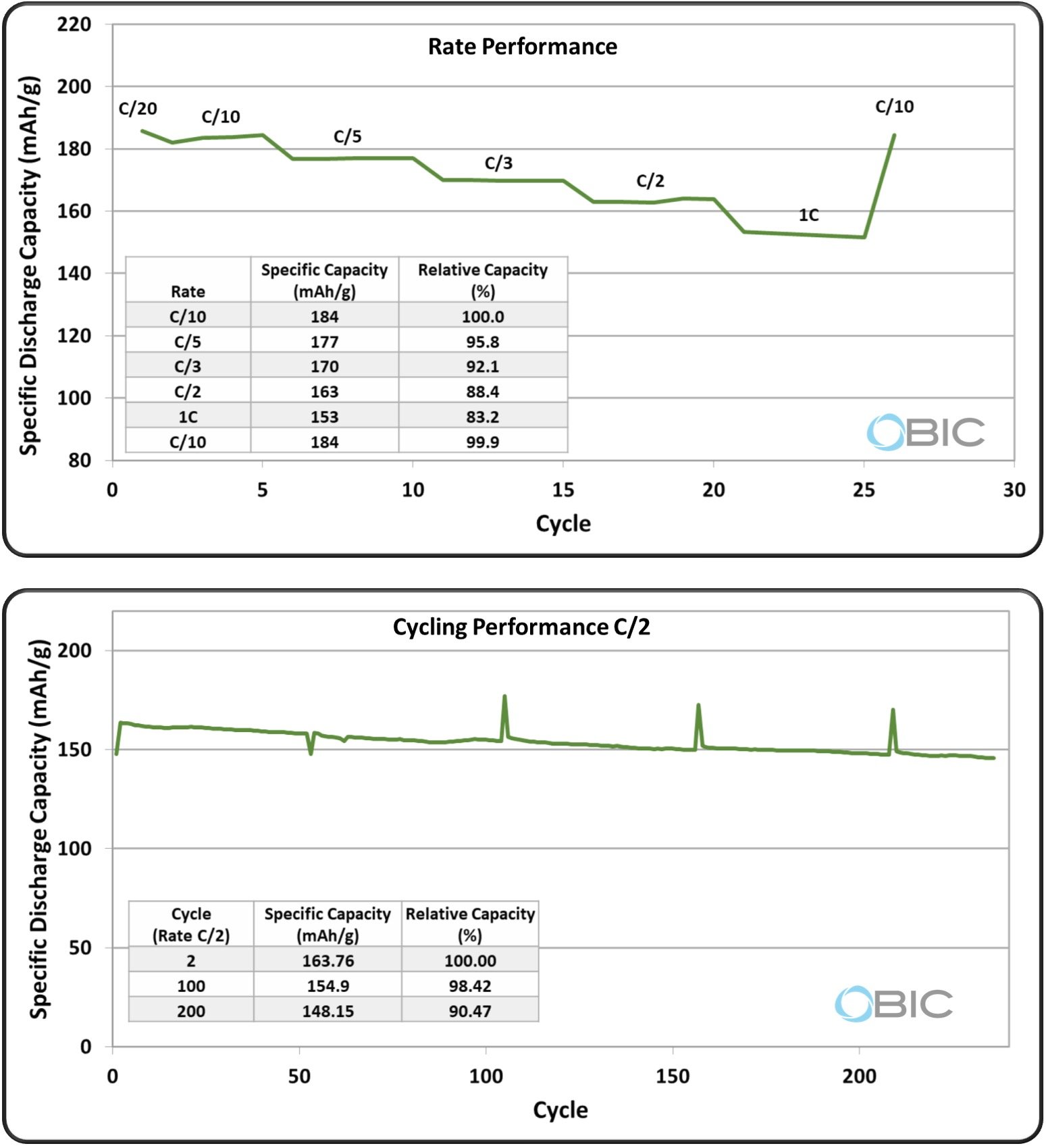

Single Layer Pouch Cell Performance

Rate Performance: Prelithiated 1.5 mAh/cm2 SiOC- coal composite anode, matched with NMC532 cathode. C/20 performed for one cycle before moving through rate progression, within the voltage window of 2.5-4.2V.

Cycling Performance: C/2 rate was selected based on rate progression performance.

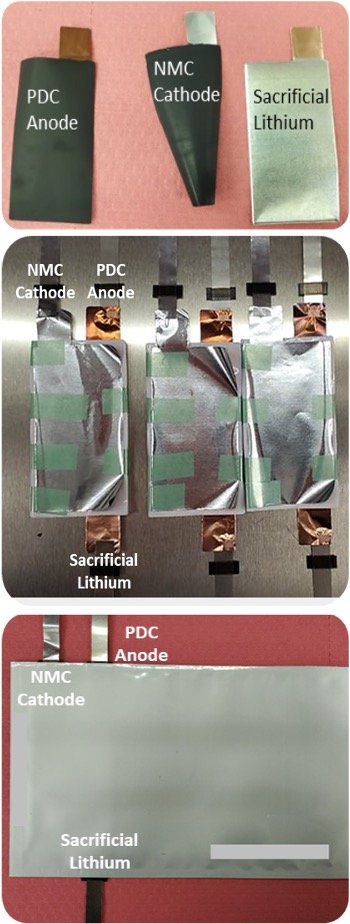

Single Layer Pouch Cell Fabrication

SLP Prelithiation / Full Cell Assembly

4.2 cm X 7.0 cm, 27 mAh cells

SiOC-coal composite anode

BASF NMC532 cathode

Electolyte: 1M LiPF6 in 1:1 v:v EC:DMC +1%VC + 1%PS + 5%FEC

For electrochemical prelithiation, cells are constructed tri-layer orientation.

Anode / Separator / Sacrifical lithium plates Cu Foil / Separator / Cathode

Initial Formation occurs between anode and lithium foil, lithium foil is removed and then secondary formation and cycling between anode and cathode proceeds.

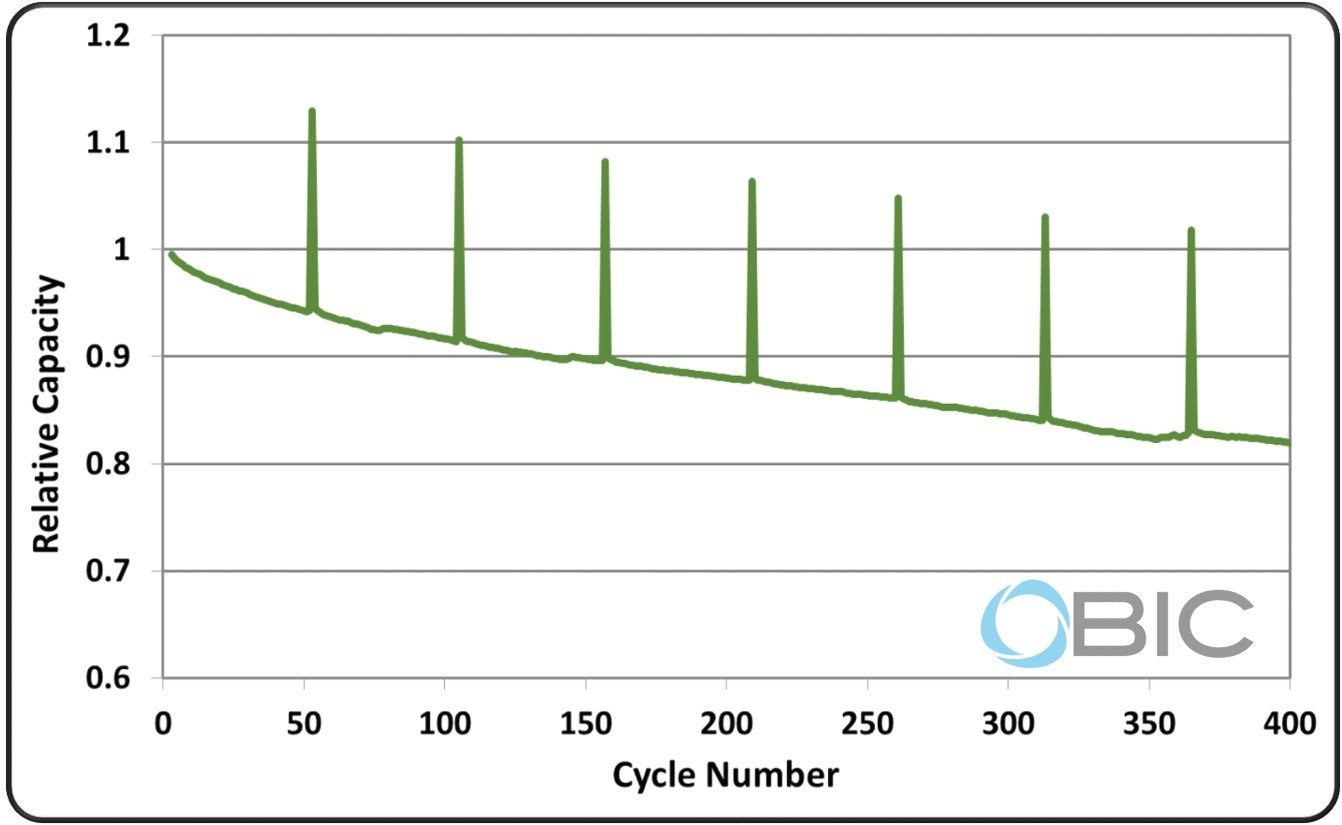

Full Coin Cell Cycling

Long-term cycling performance of prelithiated coal composite anode and NMC531 cathode, rate C/3 between 3.0-4.2V.

Full coin cell (vs NMC 532, 2.5-4.2V) surpassed 400 cycles above relative capacity of 80%.

Half-Cell Composite Performance

Cycling performance of SiOC-coal composite anodes with different polymer formulations, rate C/20 between 0.005-3.0V.

Successfully developed viable PDC/Coal Composite Anodes.

Half coin cell (vs Li, 0.005-3V) specific reversible capacities >600 mAh/g