X-BATT® TECHNOLOGY

Customized, Low-Cost, Scalable, Domestic Source for High-Performance Anode Material

What Are Polymer Derived Ceramics (PDCs)

•Polymer-Derived Ceramic (PDC’s) are the result of inert gas pyrolysis of ceramic-forming polymers processed below 1100oC.

•Can be employed as anode materials due to the crosslinked network of amorphous silicon oxycarbide (SiOC) matrix that remains electrochemically active if processed correctly.

•X-BATT® has developed low-cost and scalable methods to produce these proprietary, inorganic, resin-based technologies to create conductive SiOC ceramics for use as lithium-ion battery anodes.

•Higher specific capacities than graphitic anodes can be achieved, with better stability than mixed silicon and graphite experimental anodes.

The ceramic forming polymers can be integrated with impure carbon materials such as coal or recycled graphite with <90% purity level.

The storage mechanism for SiOC PDCs can be attributed to the nanodomains created through its amorphous structure, consisting of segregated carbon networks, nanovoids, and SiOC tetrahedral units.

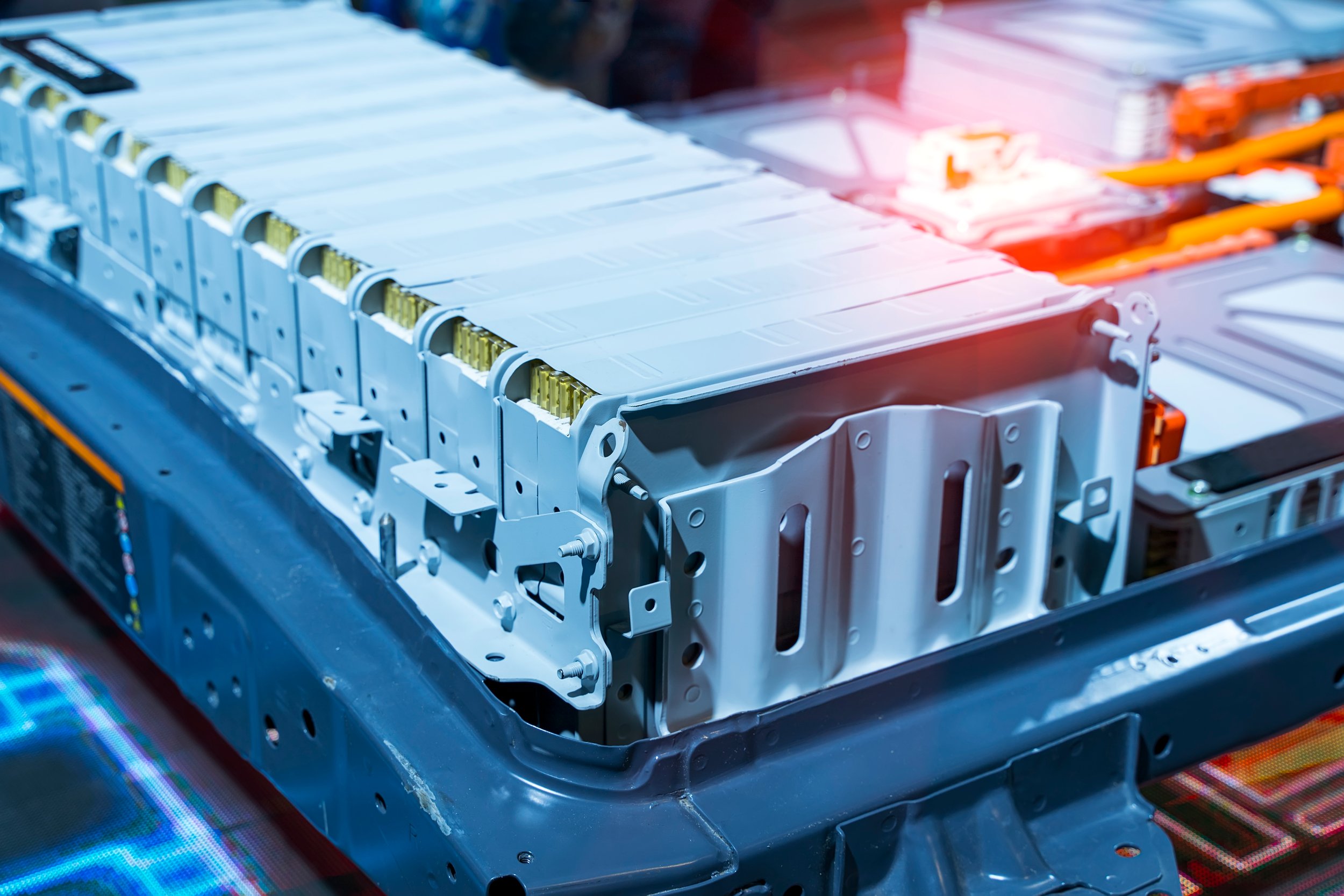

Current Technology Applications.

Recycled Graphite

Currently, 95% of lithium-ion batteries end up in landfills and are not recycled and this needs to change.

As the production of electric vehicles continues to increase, so will the demand for graphite. Currently there are no domestic sources for battery grade graphite so recycling graphite from spent lithium-ion batteries should be a priority.

Recent laboratory results have shown that with the X-BATT technology, spent graphite from end-of-life lithium-ion batteries can be up-cycled for use as high energy dense ceramic composite anodes.

Coal-based Anodes

In 2020 X-BATT was awarded a 3-Year, $1M NETL Contract to research ways to utilize coal as an anode material in lithium-ion batteries.

We have found that coal, a low-cost, abundant resource, when mixed with our proprietary resin system can significantly improve anode capacity when compared to graphite.

Through this grant we expect to demonstrate this technology in 18650 batteries in the next 2 years.

High Performance Coatings

X-BATT is developing an interface modification technology that could stabilize the solid electrolyte interphase (SEI) of anode material including silicon. This major improvement in the technology would result in more durable, longer lasting materials.